Business line

-

ISFOC's installations include Labs specifically conditioned to hold pre-certification tests of IEC 62108, and to fully characterise both indoor and outdoor CPV modules (prototypes).

Test carried out are defined in IEC 62108:2007, and those in UNE-EN 61215:2006, IEC 60068-2-21:2006 and ANSI/UL 1703 as well.

Due to the great versatility of the equipment, it is possible to hold different kinds of tests by perfectly adapting to the requirements.

In order to characterise the CPV modules: ISFOC offers a commercial Solar Simulator for CPV testing adapted to requirements of a wide voltage range (max. 400v) as well as currents (max. 10 A). Therefore, module I-V characterisation is obtained, with its maximum power for controlled values of irradiance at 25º C. By using the adjustable structure, measuring over the angular acceptance of module is also obtained 8 optical characterisation, and that way, rounding up the full CPV module characterisation.

Outdoor characterisation: ISFOC offers a versatile, outdoor, high-efficiency, two-axis solar tracking system, which, in combination with a measuring system, monitors the electric response of CPV modules. Moreover, module temperature, irradiance, and ambient conditions are also monitored. Off-axis and angular acceptance tests are also carried out by this tracker, being also able to hold the side-by-side test of IEC 62108, among others.

Lab tests correspond to accelerated aging processes, both climatic with climatic with humidity and UV radiation, as stated in IEC 62108 for CPV modules; for example, the thermal cycle test, humidity freeze, damp heat and UV exposure, haul impact, rain, mechanical load, drive and power injection test, dielectric strength, and isolation.

The lab offers all the necessary means in order to carry out the tests: high-volume Climatic Chambers, haul launcher, rain test structure, dynamometer, torque wrench, multi-meter, programmable power supplies, and isolation tester.

-

The Institute for Concentration Photovoltaics Systems was aimed to study, develop, and foster CPV energy. After more than 5 years since the creation of ISFOC, CPV energy now holds a prominent position in the photovoltaic area, being competitive regarding investment/energy production. However, CPV technology has a number of peculiarities different from other photovoltaic technologies that should be taken into account and analysed before the construction or investment in a CPV plant, such as the weather conditions, the dimensions, and equipment selection.

The proposed methodology below has been successfully used by ISFOC. That is the reason why ISFOC recommends dividing the tasks into 4 phases to be carried out consecutively, the first phase being crucial and totally essential before planning the construction of a plant, whether CPV or any other technology, with some degree of success:

- Phase 1: Technical feasibility report of the project

- Phase 2: Call for tenders, Engineering, and Construction

- Phase 3: Determination of power and Acceptance tests

- Phase 4: Monitoring and performance assessment

-

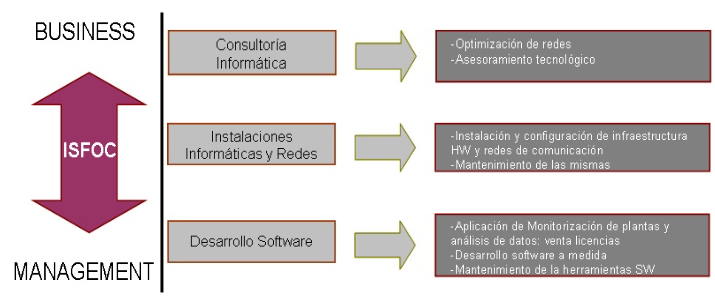

ISFOC's Software Engineering Department, devoted to Renewable Energies, specializes in Consultancy projects, Equipment maintenance, Communications networks, Hardware installations, and Software development.

The department's main goal is to contribute in competitiveness, innovation, and evolution capacity for its customers, while covering their demanded requirements. Great knowledge, experience, and service capacity, a high level of Technological background, as well as a deep awareness of the Renewable Energies field in compliance with a solid platform of our own products are the key points that form a strong pillar for supporting our solutions.

ISFOC presents a Software services & products catalogue covering every stage of the Renewable Energies Informational technologies, especially Concentration Photovoltaics (CPV), from the CPV plants’ monitoring to maintenance and data analysis as well as Predictive models of production.

The Software Engineering department is comprised of a unique Hardware and Software structure worldwide; it has a huge informational database that manages the monitoring and analysis of the data collected from several different prototypes and CPV plants located in various locations around the world (Spain, Egypt, Morocco, Abu Dhabi (UAE)). The technologies analysed are provided by 10 different manufacturers (Arima, Soitec, Isofoton, Solfocus, Arima, Sol3G, Emcore Energy Innovations, Everphoton, Magpower, Semprius, and Daido).

Those solutions allow for the optimization of the technology and CPV plant production as well as making management, analysis, and maintenance easier. Consequently, all of those improvements will directly lead to a reduction in the cost of installation and maintenance of the CPV technology.

Services

-

ISFOC currently owns all the necessary equipment to carry out the evaluation of CPV technology. This evaluation is held both at module level as well as at the whole system or concentrator's level (tracking system plus modules), and regardless if they are connected or not.

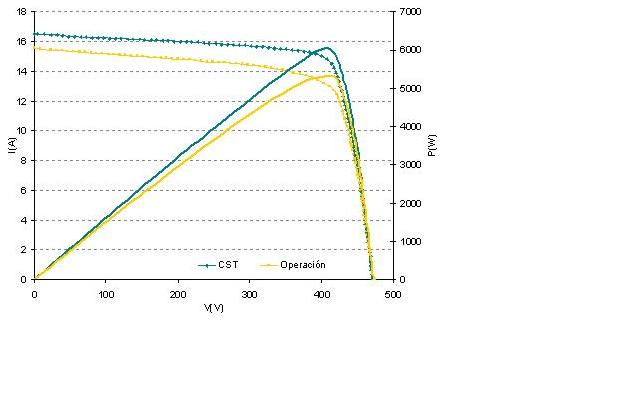

At the concentrator's level, the same characterisation in real operation conditions can be held, apart from comparing it with the results obtained for the module. With this info, an initial analysis can be made of the concentrator’s performance by identifying the main factors of energy losses, such as misalignment between the framework modules or dispersion between them, inverter losses, or wiring faults.

Module evaluation consists in rating the Nominal Power in standard measuring conditions as well as checking and determining the performance in different operative conditions that may occur in different CPV technology locations. All the tasks are being carried out in compliance with the IEC 62670 standard, "Concentration Photovoltaic (CPV) Module and Assembly Performance Testing and Energy Rating," that is being currently developed with the active participation of ISFOC, which is feeding back its results to the Scientific International Committee.

ISFOC currently owns all the necessary equipment to carry out the evaluation of CPV technology. This evaluation is held both at the module level as well as at the whole system or concentrator's level (tracking system plus modules), and regardless if they are connected or not.